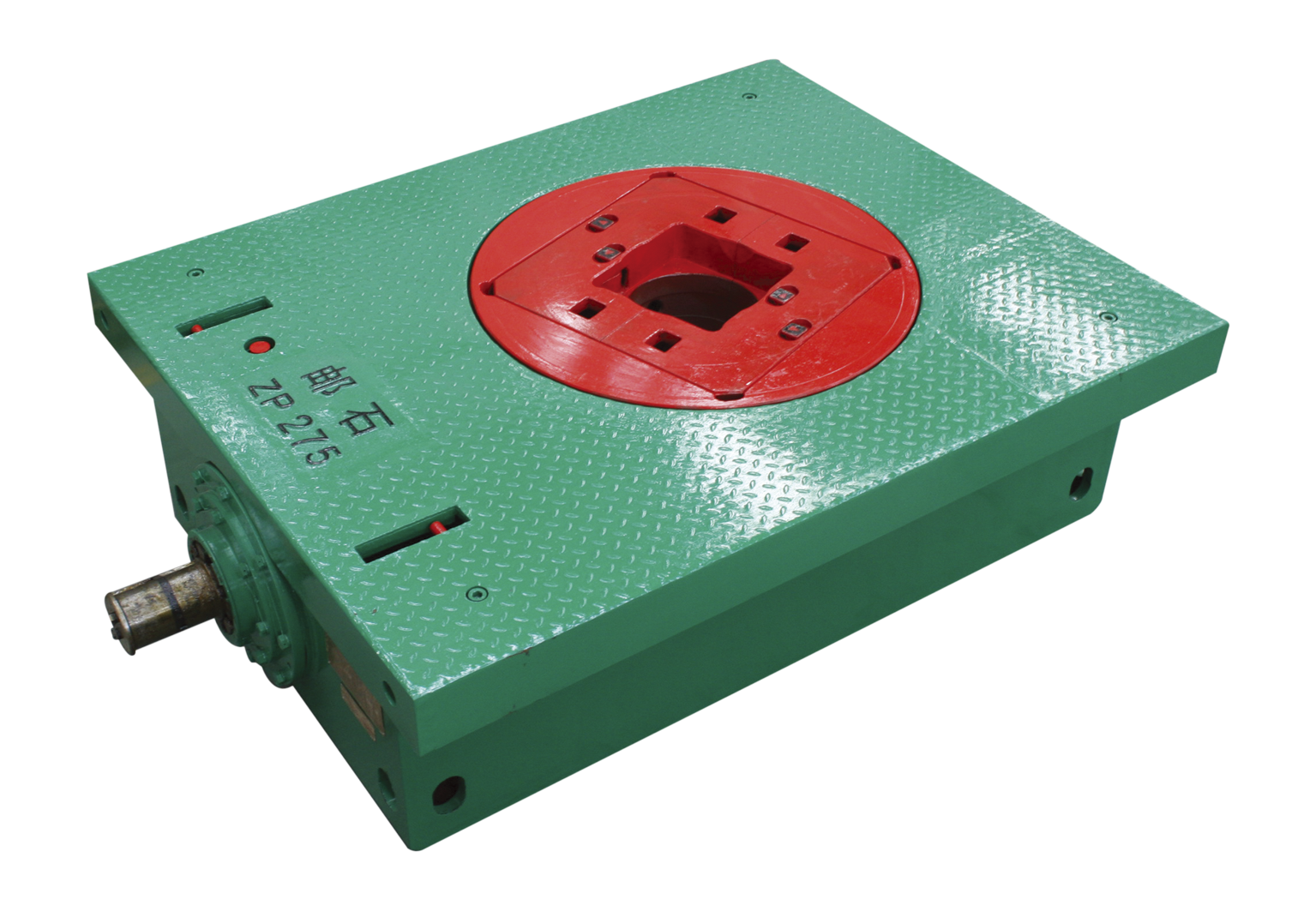

Rotary Table

- Rotary table overview

The rotary table is the key equipment of the rotary drilling machine. In the drilling process, the well drilling can be realized by the rotation driving drill stem and drill bit of the rotary table. In the process of tripping unit and running casing, it is necessary to clip the pipe column on the rotary table to brake out a joint.

- Function and operation requirement of Rotary table

2.1 Function of the rotary table: the drilling tools in the rotation well transmit large enough torque and the necessary revolving speed; when running casing or tripping unit, it bears the weight of all casing strings or drill column in the well; and it completes the work of removing drill, braking out a joint, back off in the process of accident handling and bears the reaction torque.

2.2 Operation requirements of rotary table: the main bearing of the rotary table shall have sufficient strength and life in order to bear the weight of the hundreds of tons of casing strings or drill columns. It has enough lifetime under the function of the maximum axial load and axial and radial load caused by the transmission of the angular wheel when the drill column gliding; Rotary table and angular wheel can transmit large enough torque and can reverse and reliably brake; and it has good leakproofness, prevents the outside mud and mud permeating the rotary table and slows down the wear of gear and bearing.

- Structure and working principle of rotary table

3.1 Rotary table structure: rotary table is mainly composed of the horizontal axis assembly, rotary table assembly, main and auxiliary bearings and shells and other components.

Horizontal axis assembly: the head of the horizontal axis is provided with bevel pinion, and the tail is provided with coupling flange or chain wheel. All parts are fitted in the sleeve, and the sleeve plays the role of enabling the horizontal axis assembly to conduct the whole assembly.

Rotary table assembly: the large conical gear is installed outside the rotary table, which is installed at the shell by the main bearing seat. The lower auxiliary bearing can prevent rotary table from inclining and jumping upwards. The upper part of the rotary table is provided with labyrinth seal which can prevent mud and sewage from entering into the rotary table oil pool.

Main and auxiliary bearing: the main bearing plays the role of bearing and forwarding. Auxiliary bearing plays the role of radial centralizing and axial spring prevention.

Shell is steel casting or cast-weld component with relatively complex and solid structure and there are two oil pools in the inner cavity.

3.2 Working principle of rotary table: the power of the modern drilling rotary tables composed of the above parts is passed in by the flange or chain wheel on the horizontal axis. The rotary table is rotated by the angular wheel, the kelly stem, drill pipe and drill are driven to rotate by the main bushing and kelly stem bushing in rotary table through-hole. At the same time, the kelly stem bushing allows the axial free slide of drill pipe to realize the rotation and feed-in of the drill pipe. In the process of tripping unit and running casing, the drill pipe or casing can be placed on the rotary table with slips or hanging seat.